If you’ve ever wanted to make your own shelf brackets and weren’t sure where to begin, then this is your lucky day. It’s a fun project and lets you customize for your needs and save some money too. Follow along as I make some low-profile shelf brackets.

I’ve been renovating our upstairs bathroom and decided we needed a shelf above the sink. I love the idea of a floating shelf, but it won’t work in this location. So instead, I’m going to need some metal shelf brackets that don’t take up much vertical space on the wall.

How to make your own shelf brackets

If you head to the hardware section of your local home improvement store, you’ll find corner braces like these. They’re not especially expensive, but if you need a lot of them, it could add up quick.

Each leg of these pre-made braces is the same length. So I would need to cut one side down and then drill another hole to replace the one I cut off. If I’m going to be modifying the bracket, I might as well make my own. Right?

Here you can see that in my local Lowe’s metal stock bin, I have a lot of flat bar to choose from. The one I picked out is a 3ft length of thicker and wider steel than what the corner braces were made of (that means stronger). For less than two braces, I can probably make 6 shelf brackets with this flat bar.

The first thing I did was to mock up a bracket with cardboard. I held it in place in my bathroom with the wood I wanted to use for the shelf. The long leg is about 3/4 of the width of my shelf board. The short leg is just long enough to fit two mounting screws and withstand the weight I expect on my shelf.

Note: The more weight you expect on your shelf, the taller the bracket should be. The number of brackets you use will affect its strength as well. They will all share the load. So keep these things in mind while deciding your bracket size.

Once I was comfortable with the dimensions, I made some marks for screws and transferred everything to the flat bar. I didn’t cut or bend it just yet. It’s a lot easier to work with while it’s flat and long enough to hold.

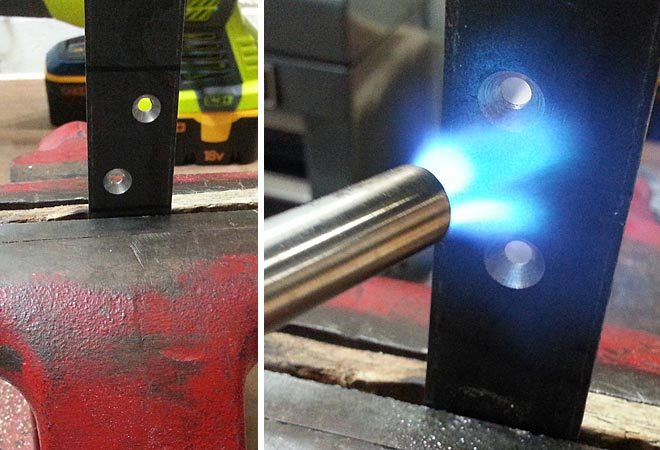

While the bar was still flat, I drilled the holes and countersunk them so the screws would sit flush when mounted. I used my drill press for this, and I’d recommend it, but you can definitely do the same with a hand-held drill. Just be careful and use cutting oil either way.

Next I mounted the flat bar in the vice with the bend line just above the top of the jaws. I tried bending the bar by hand but it was very difficult and wanted to bow along its length. So instead I lifted up the bar, heated the bend line with a torch, and remounted it in the vice.

Depending on the thickness of your flat bar, you may not need to heat it and may have a real easy time bending it. For me though, heating it helped and I was able to get the 90 degree angle I wanted.

For my second bracket, I tried pulling with my hand while hitting the bar with a hammer. The closer to the bend point you hit the metal, the tighter of a bend you’ll get. Adjust this for the look you want.

The hammer method worked well too and didn’t require a torch. But you might want to wear ear protection.

Once the bracket was bent, I mounted it sideways in the vice and cut it. A hacksaw or reciprocating saw work well enough for cutting through. However, I’d recommend an angle grinder with a cut-off wheel.

Last thing to do is clean up the cuts. I used a fine metal file and softened all the edges and corners. It’s easier to do this with the bracket mounted in the vice. If you have a light touch, you could use the grinder as well.

If there were any changes you made to the length or position of the holes or the bend while making the bracket, verify them now. Once you’re happy with the final product, make more! Make your changes to the template and duplicate as many times as you need.

And that’s it. You’ve got enough metal to make at least a few more brackets. In my case, 6 brackets for less than the cost of two.

Let me know in the comments if you tried this and how it went.

Final Thoughts

Please keep in mind that for low profile brackets especially, you have to be careful with how much weight you hold. Probably more important is leverage. Don’t expect a short wall-mount like these to withstand much on the edge of a deep shelf.

It’s preferable to use long, beefy screws and to mount these brackets directly into studs. If you can’t manage that, then use quality drywall anchors.

Lastly, the raw metal look is a good one. But if you’re trying to go low-profile to hide the brackets, then clean all the oil off of them and paint them the same color as the wall. That’s what I plan to do with these in my next project.

What tutorial do you want to see next?

I hope you liked this one and give it a try. What how-to would you like to see next? Let us know in the comments below.