Edge banding is a common way to dress up plywood furniture. But what if you’re not looking for finesse? What if you need a simple, rugged solution? In this tutorial, I’ll show you how to use spray-on bedliner as an edge banding technique for wood.

Experimenting with automotive coatings

I’ve been building my new desk and I wanted to find a better solution to cap my plywood edges. I don’t like wood veneer edge banding because I tend to use cheap plywood and have difficulty getting a smooth, strong bond. I also don’t like the cost.

So I tried Rustoleum Undercoating, a rubberized, thick coating that is commonly used to protect the frame and underside of a vehicle. I also tried Rustoleum Truck Bed Coating, a bed liner product that dries very hard and has a tough texture to protect the bed of a truck.

I put these head to head on the edge of a scrap of plywood. After three coats each and a couple days to fully cure, I tested them for feel, durability, and coverage.

Feel

The rubberized undercoating was certainly more pleasant to interact with. It was firm but had a little give to it and didn’t scratch my wrists when I slid them across it. I will be resting my wrists and forearms on the edge of the desk, so this was an important test. The bedliner wasn’t rough enough to hurt me, but it was much more abrasive.

Durability

Here is where my decision was made for me. After two days of curing, I couldn’t scratch either product off the plywood edge without the use of a tool. This was fantastic, however I found that the undercoating was leaving a black residue on my fingers when I rubbed it. This would not work for me as I didn’t want to get anything on my clothes or on the walls when the desk was installed in my office.

Coverage

Both products covered equally. I was surprised to find that some of the underlying plywood texture did show through, even with three coats. I made a mental note to prepare the edge by sanding and filling voids on my desk top to reduce this.

In the end, I decided on the truck bed coating. Bedliner as edge banding, for application on my desk top, will work great.

Preparation

To prepare for applying the bedliner to my project, I first finished the top and bottom of the plywood desk top. This included all top coats and waiting for the finish to cure. I don’t believe you’ll want to work on the top surface after you apply the bedliner as its texture will make masking difficult and I’m not sure that it sands easily.

After sanding the rough edge and filling voids with wood filler, I finish sanded with 220 grit sandpaper. You can go higher than this, but it won’t make much difference because the texture of the spray-on bedliner will cover it up.

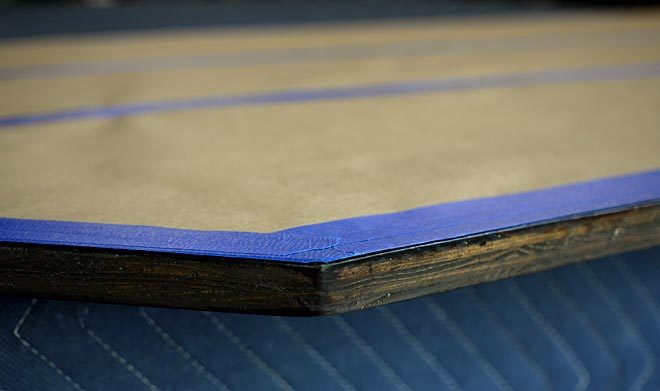

I then used painters tape on the top and bottom edge to mask off the finished surfaces. I filled in the top and bottom faces with masking paper and tape to avoid any over-spray.

Spraying bedliner

Because of the rough texture, I didn’t have to worry about dust, so I took my project outside to spray. You’ll want to make sure you have adequate ventilation, just like with any spray paint. Following the label, I gave the edge three coats, waiting just a few minutes in between coats. I made sure to angle the nozzle up and down at the edge on different passes so as to get even coverage of the top and bottom lip.

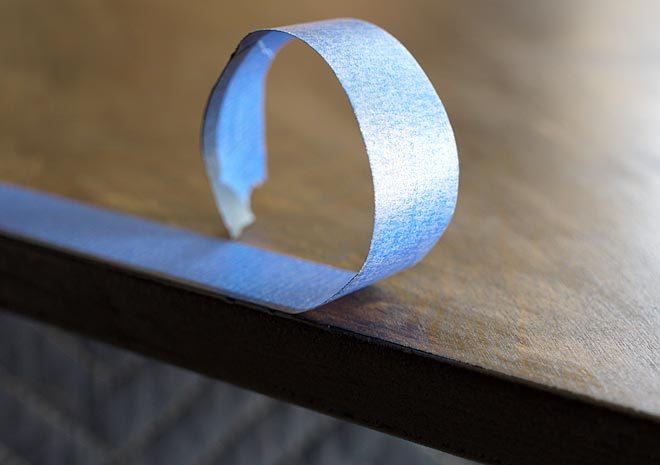

I waited about 15-20 minutes on a warm day and then removed the masking, making sure not to disturb the still-curing bedliner.

Peeling off the tape showed a really crisp edge. I really liked the look of it, and so far it hasn’t been too sharp on my wrists.

Results

I absolutely love this Rustoleum Truck Bed Coating. I’ve used it on my shop truck and various metal projects, and now I can say that I successfully used it on plywood furniture!

The desk top was put on temporary legs and used the very same day I sprayed the bedliner edge banding. I’m sitting at this desk right now to write this tutorial. I’m really impressed by how durable the edge feels and I am not uncomfortable at all leaning on it.

While standard black bedliner worked perfectly for my dark desk top, it may not suit your needs with different stains and wood species. However, it does come in a tan color too, and that could hide reasonably well with most natural finishes on plywood.

Spray-on bedliner from a can is an amazing thing. If you have a shop truck, chances are you’ve used it before. It’s a tough, permanent coating for your truck bed, bumper, and anything else metal that you want to protect. Since your shop truck gets a lot of abuse, it makes sense to protect it.

But now you know that you can use it on wood too.

Is this the right solution for you?

I certainly can’t say this is the perfect edge banding technique for all situations. But I do have a few in mind where it seems very applicable:

- Tables and desks that get a lot of abuse.

- Children’s furniture, especially outdoor furniture.

- Workshop furniture like workbenches.

That last one really intrigues me. I am strongly considering edge banding all my new workbenches with spray-on truck bedliner. While hardwood trim and veneer would look really nice, I think this simple, cheap solution could give them a run for their money. Bedliner as edge banding is my new favorite furniture hack!

What other uses can you think of for bedliner?

Let me know in the comments what you come up with!